In recent years, the construction industry has witnessed a remarkable transformation with the integration of nanotechnology into various building materials. One such breakthrough is the application of nanotechnology in cement, paving the way for stronger, more durable, and sustainable structures. This article explores the implications of nanotechnology in cement, shedding light on the innovative developments that promise to reshape the future of construction.

Understanding Nanotechnology:

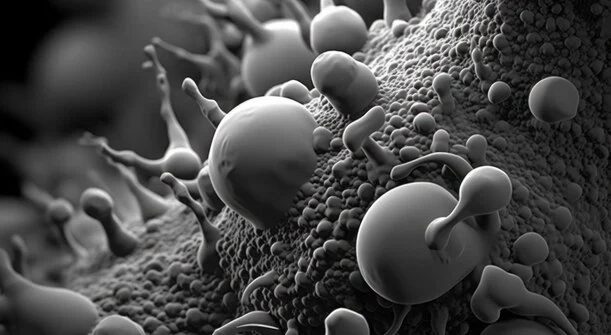

Nanotechnology involves manipulating materials at the nanoscale, typically at dimensions smaller than 100 nanometers. In the context of cement, this means manipulating the structure of cement particles at the molecular level. The utilization of nanoparticles offers unique properties and functionalities that can enhance the performance of traditional cement in numerous ways.

Enhanced Strength and Durability:

One of the primary advantages of incorporating nanotechnology into cement is the substantial improvement in strength and durability. By reducing the size of cement particles to the nanoscale, the surface area increases significantly. This increased surface area allows for better bonding between particles, resulting in a denser and more robust concrete matrix.

Additionally, nanomaterials such as silica fume, fly ash, and graphene can be added to the cement mixture. These additives reinforce the structure by filling in the gaps between larger particles, making the concrete more resistant to cracking and increasing its load-bearing capacity. As a result, structures built with nanotechnology-enhanced cement exhibit enhanced durability and longevity.

Self-Healing Properties:

One of the groundbreaking features of nanotechnology in cement is its potential for self-healing. Microcracks can develop in concrete over time due to various factors such as shrinkage, temperature fluctuations, and loading conditions. Nanoparticles, when strategically incorporated into the cement mix, can react with moisture in the environment to form calcium carbonate, effectively sealing the microcracks and preventing further deterioration.

This self-healing capability not only prolongs the lifespan of structures but also reduces maintenance costs. The concept of self-healing cement holds great promise for sustainable and resilient infrastructure.

Improved Thermal and Conductive Properties:

Nanotechnology in cement also contributes to improved thermal and conductive properties. Nano-sized particles disperse more uniformly throughout the concrete, creating a more efficient thermal barrier. This can lead to better insulation, reducing energy consumption for heating and cooling in buildings. Additionally, the enhanced conductivity allows for the integration of smart technologies, such as sensors, into the concrete structure for real-time monitoring of structural health.

Environmental Impact:

Beyond performance improvements, the application of nanotechnology in cement aligns with the growing emphasis on sustainability in construction. The reduced need for cementitious materials due to enhanced strength and the incorporation of supplementary materials like fly ash and silica fume contribute to lower carbon emissions associated with traditional cement production.

Challenges and Considerations:

While the potential benefits of nanotechnology in cement are significant, there are challenges and considerations that researchers and industry professionals must address. These include the cost of production, potential health and environmental impacts of nanoparticles, and standardization of manufacturing processes. As technology continues to advance, it is essential to tackle these challenges to ensure widespread adoption

Nanotechnology in cement represents a paradigm shift in the construction industry, offering a multitude of benefits ranging from improved strength and durability to self-healing properties and enhanced sustainability. As research and development in this field progress, the integration of nanotechnology into mainstream construction practices is poised to redefine the way we build and maintain infrastructure. The journey towards more resilient, sustainable, and innovative structures has only just begun, with nanotechnology in cement leading the way into a future of cutting-edge construction.