Constructing a house or any structure is an exhilarating endeavor, and it all starts with choosing the appropriate building materials. The construction sector provides a diverse range of materials, each possessing distinct properties and serving specific purposes. In this article, we’ll delve into ten types of building materials commonly employed in construction projects.

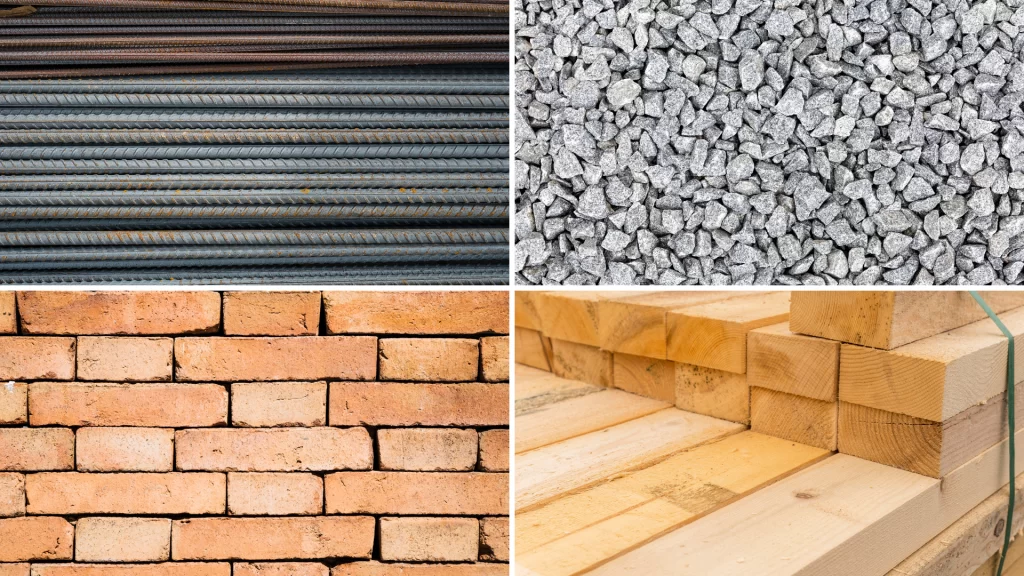

Categories of Construction Materials

Building materials are typically categorized into two primary origins: natural and manmade. However, regardless of their source, these materials often undergo processing or treatment before being utilized in construction. Below is a list of materials commonly employed in building construction:

Steel:

Steel, a robust metal alloy comprising iron and carbon, is further fortified with additional elements to enhance its strength and durability. Variants like stainless steel contain chromium, offering superior resistance to corrosion and oxidation. Despite its weight, steel remains a preferred choice for constructing contemporary buildings and large industrial facilities due to its remarkable structural integrity.

Cement:

In building, cement plays a vital role as a cohesive agent that unites components and reinforces durability. It is rarely used on its own but is usually combined with gravel and sand. Blended with fine sand, it forms mortar, which is used to join bricks and stones in building projects. On the other hand, cement transforms into concrete, a versatile material used in a variety of construction projects, when combined with sand and gravel. Cement, which is highly valued for its ability to create strong bonds and solidify, is an essential component of construction that ensures the durability and longevity of buildings and structures.

Concrete:

Concrete stands as a distinctive construction material crafted by combining various aggregates such as gravel, crushed stone, recycled concrete, and synthetic elements. These components amalgamate with a liquid binder, typically cement, which solidifies gradually as it dries. The prevalent type of cement utilised in this process is Portland cement, derived from heating limestone and clay, with gypsum subsequently added. When Portland cement is blended with water and aggregates, it metamorphoses into the robust substance known as concrete. This formidable material forms the foundation for numerous structures ubiquitous in our surroundings.

Ready Mix Concrete:

Ready mix concrete emerges as a convenient building material manufactured in off-site plants and transported to construction sites pre-mixed and primed for use. It constitutes a precise blend of cement, aggregates like sand and gravel, and water, meticulously measured and mixed at concrete plants. This pre-prepared mixture guarantees uniformity and excellence, streamlining construction processes by saving time and labour on-site. Contractors can effortlessly pour ready mix concrete into moulds or formwork, ensuring precise placement and efficient curing. Occasionally, an additional component known as an admixture is incorporated to enhance concrete’s workability or regulate its setting time, facilitating its transportation to construction sites.

Binding Wire:

Binding wire assumes a critical role in construction by firmly securing various components together. It proves particularly valuable for fastening reinforcing bars (rebars) at junctions, thereby enhancing the structural integrity of the building. Typically crafted from mild steel, binding wire serves as an essential element in ensuring the stability and coherence of construction projects.

Wood:

Framing a new wooden house involves using wood, a versatile natural building material obtained from trees, trusted for centuries. Wood is valued for its strength, durability, and aesthetic appeal, making it a popular choice for construction, furniture, flooring, and many other applications in the building industry. It is typically used in various forms such as lumber, timber, boards, and planks when cut or pressed.

Additionally, wood is an environmentally friendly option when sourced responsibly. Forest Stewardship Council (FSC) certification ensures sustainable forest management, promoting conservation, biodiversity, and supporting local communities.

Stone:

Natural stone has been a fundamental building material for centuries, formed through geological processes over time. Types of stone like granite, limestone, and marble each offer unique colors and textures. Stone is commonly used for foundations, walls, flooring, and decorative elements due to its strength and durability. Its robustness makes it capable of withstanding harsh weather conditions, ensuring both long-lasting performance and a rustic aesthetic appeal.

Bricks:

Bricks are one of the oldest building materials in construction, typically made from clay and fired in a kiln. They are used for constructing walls, buildings, and various masonry projects. Bricks come in various shapes, sizes, and colors, allowing for versatile design possibilities. Known for their durability and insulating properties, bricks provide both strength and a classic, traditional look to architectural projects.

Blocks:

Blocks are modular construction units made from materials such as concrete, clay, or aerated concrete, varying in shape and size for specific construction needs. They are essential for creating walls, partitions, and structural elements in construction projects. Blocks are known for their strength, stability, and ease of installation, making them a practical choice for both residential and commercial buildings.

Aggregates:

Aggregates are granular materials used in construction, consisting of crushed stone, gravel, sand, or recycled materials like concrete and asphalt. These materials form the foundation for various construction projects, including roads, buildings, and bridges. Aggregates provide structural support, aid in weight distribution, and enhance the strength of concrete and asphalt mixtures. With a range of sizes and types available, aggregates can be tailored to meet specific construction requirements.

Constructional Binding Wire (Straightened Cut Wire):

Specially crafted for construction projects, offering robust and secure fastening solutions.

Black Annealed Binding Wire: Perfect for everyday tying requirements, this wire is easy to handle and ensures a firm grip.

Galvanised Iron Binding Wire: Galvanized against corrosion, this wire boasts durability, making it suitable for enduring applications.

Tie Loop Tie Wire: It is versatile and adaptable for various tying applications in construction settings.

Binding wire for packing: Primarily employed in packaging to safeguard materials and goods during transit.

U Type Binding Wire: Shaped like the letter “U,” this wire is customised to fulfil specific binding needs.

Galvanized Wire: It offers enhanced protection against rust, making it well-suited for outdoor usage.

Stainless steel wire: Withstanding corrosion, this wire finds utility in outdoor and marine environments.

Brass Wire: recognized for its strength and resistance to corrosion, it is widely utilised across diverse industries.

Aluminium Wire: Characterized by its lightweight nature and corrosion resistance, it is ideal for weight-sensitive applications.

PVC binding wire: Featuring additional protection, this wire is commonly employed in outdoor and harsh environments owing to its weather-resistant properties.

When embarking on the journey of building a home, selecting the appropriate building materials holds paramount importance. UltraTech Building Solutions presents an extensive array of construction materials, encompassing cement, concrete, and ready-mix solutions. With this diverse selection, finding the ideal match for your construction requirements becomes effortless.

Why Choose SRMPR Cements for Cement Construction:

- Superior Quality: SRMPR cements are renowned for their exceptional quality, ensuring the longevity and durability of your construction projects.

- High Strength: SRMPR cements boast high compressive strength, providing robust support to structures and enhancing their stability.

- Consistent Performance: With stringent quality control measures in place, SRMPR cements deliver consistent performance, guaranteeing reliability in construction endeavors.

- Versatile Applications: SRMPR cements are suitable for a wide range of applications, from residential buildings to infrastructure projects, making them highly versatile.

- Trusted Brand: SRMPR is a trusted and reputable brand in the cement industry, synonymous with reliability, innovation, and excellence.

By choosing SRMPR cements for your cement construction needs, you can rest assured that you’re investing in top-notch quality and performance, laying a solid foundation for your dream home or project.