In the construction of brick or stone structures, more than just a sturdy foundation or precise material arrangement is required. Attention to detail distinguishes an ordinary project from a visually striking masterpiece. Among these details, pointing stands out as a crucial element contributing to both structural integrity and overall aesthetics in masonry. In this blog post, we’ll immerse ourselves in the realm of pointing in construction. We’ll uncover its significance, delve into the different types of pointing, discuss their benefits, and examine the purposes they serve. Whether you’re a construction aficionado, a homeowner seeking insights into masonry intricacies, or simply intrigued by the art of pointing, this blog will furnish you with the understanding to appreciate the importance of this construction technique.

What is pointing in construction?

What exactly is pointing in construction? In essence, it involves filling the gaps between bricks or stones with mortar or other suitable materials. While this task may seem mundane, can the proper execution of pointing truly turn a regular wall into a work of art? Moreover, does pointing serve purposes beyond aesthetics, and what advantages does it offer for the longevity and functionality of a construction project?

Exploring Various Types of Pointing in Masonry

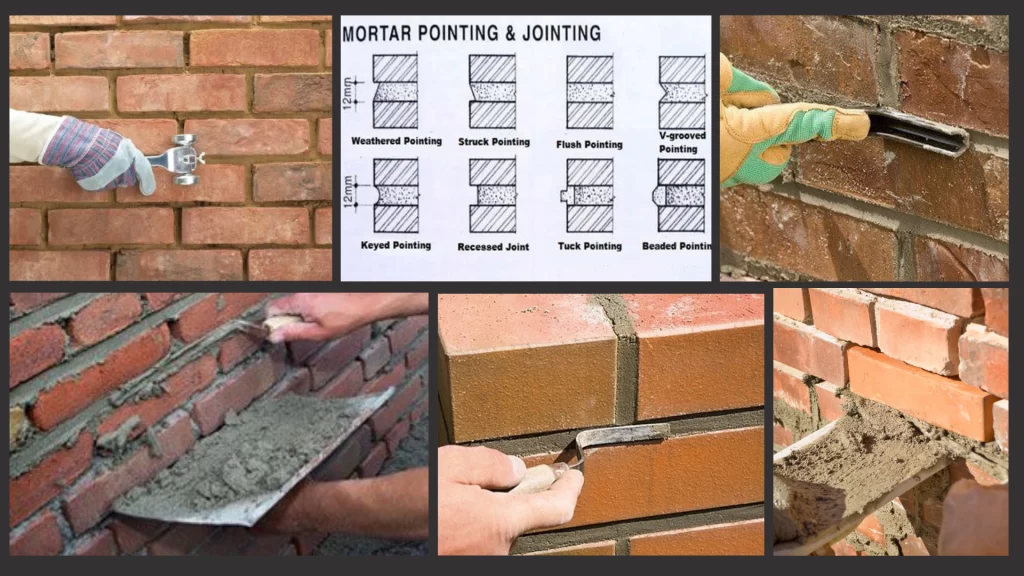

Pointing in construction encompasses a diverse range of techniques, each offering its own distinct visual appeal and functional benefits. Let’s delve into some prominent types of pointing used in masonry:

Flush Pointing:

Flush pointing is a widely used and durable technique where raked mortar joints are filled with mortar and excess material is meticulously removed, resulting in a smooth finish flush with the face of the brick or stone masonry. This creates a visually pleasing appearance while enhancing longevity and cleanliness by eliminating spaces that can accumulate dust or water.

Recessed Pointing:

In recessed pointing, mortar is pressed into raked joints and pressed inside the wall surface, creating a depth of around 5 mm or more while keeping the face of the pointing vertical. This technique adds depth and shadow lines to the masonry, enhancing its aesthetic appeal.

Beaded Pointing:

Beaded pointing involves pressing mortar into the joint and creating concave grooves using a steel tool with a concave shape. This results in a mortar joint with a distinctive beaded appearance, adding elegance to the overall aesthetic.

Struck Pointing:

Struck pointing involves a two-step process where mortar is filled and pressed to match the face of the brick masonry work, followed by pressing the top edge of the joint inward to create a slope. This sloping effect allows rapid drainage of rainwater, minimizing water retention on the masonry surface.

Rubbed, Keyed, or Grooved Pointing:

Similar to flush pointing, this technique involves filling raked joints with mortar and leveling it flush with the face of the masonry. What sets it apart is the addition of a groove formed at the center using a specialized tool, adding a distinct visual element to the pointing.

Tuck Pointing:

Tuck pointing is a precise technique where mortar is filled into the joint and a groove is created at the center. This groove is then filled with white cement putty, creating a contrast between the mortar and putty and enhancing the overall appearance.

V Pointing:

In V pointing, mortar is pressed into the joint, and a V-shaped groove is formed within the joint using a specialized tool. This technique creates a distinctive appearance, adding visual interest to the masonry.

Weathered Pointing:

Weathered pointing involves pressing mortar into a joint and then skillfully pressing back the top portion of horizontal joints while the mortar is still fresh. This creates a sloping effect, giving the appearance of weathered or worn-down edges.

Advantages of Pointing in Construction

Pointing plays a pivotal role in enhancing both the durability and aesthetics of masonry structures. By effectively filling the gaps between bricks or stones, pointing offers numerous advantages that contribute to the overall quality and value of a building. Here are some key benefits of various types of pointing in construction:

Enhances Structural Integrity: Proper pointing ensures a stronger building by reinforcing mortar joints and providing stability to the overall structure.

Weatherproofing: Pointing serves as a protective barrier, shielding external walls from moisture and preventing water penetration, thereby increasing the longevity of the masonry.

Restores Appearance: Pointing improves the overall appearance of the building, enhancing its aesthetics by highlighting patterns, thickness, colors, and textures of the joints.

Increases Property Value: Well-executed pointing can significantly enhance the curb appeal of a property, making it more desirable to potential buyers and increasing its market value.

Reduces Maintenance Needs: Effective pointing minimizes the need for ongoing maintenance by sealing gaps and preventing water damage, thereby saving both time and costs in the long run.

Purpose of Pointing in Construction

Protection: Pointing safeguards mortar joints from atmospheric damage, ensuring their durability and strength over time.

Aesthetic Enhancement: Pointing enhances the visual appeal of the wall by accentuating joint patterns and textures, contributing to the overall aesthetics of the structure.

Weatherproofing: By sealing gaps and cracks, pointing prevents rainwater and dampness from infiltrating the masonry, enhancing its resistance to external elements.

Strengthening: Properly filled and reinforced mortar joints add strength and stability to the masonry construction, improving its structural integrity.

Preservation: Effective pointing helps preserve the integrity of the building by preventing water penetration and subsequent damage to the underlying structure.

Types of Mortar

Lime Mortar: Prepared by blending fat lime, fat sand, and water, lime mortar offers excellent workability and flexibility. It is commonly used in both old and new structures, with ratios typically ranging from 1:2 to 1:3.

Cement Mortar: Created by blending cement, sand, and water, cement mortar provides high strength and durability. With a typical ratio of 1:3, it is suitable for various types of masonry work, offering excellent structural support.

Pointing in construction plays a vital role in enhancing structural integrity, providing weatherproofing, restoring appearance, and reducing maintenance requirements. Selecting the appropriate pointing techniques and mortar types is essential for achieving long-lasting and aesthetically pleasing results in brick or stone structures.

Moreover, when it comes to reliable construction materials, consider SRMPR Cements. With a commitment to excellence, SRMPR Cements offers a range of high-quality products designed to meet the diverse needs of construction projects. Choose SRMPR Cements for superior performance and durability in your construction endeavors.